PennDOT Maintenance Activities

Although PennDOT crews are common sights on Pennsylvania's 40,000 roadway miles and 25,000 bridges, many of our customers may not realize the scope of work we do. The Maintenance First series was developed to shed some light on the operations PennDOT performs year-round in our mission to provide an efficient transportation system. You can also see

how potholes are formed (PDF).

JUMP TO: Surface Treatment |

Shoulder Cutting |

Shoulder Grading |

Pipe Replacement & Cleaning |

Mechanized Patching |

Manual Patching |

Joint & Crack Sealing |

Winter Operations |

Vegetation Management |

Line Painting |

Bridge Maintenance & Cleaning |

Signing

Click to open PDF. (Printable PDF)

Click to open PDF. (Printable PDF)

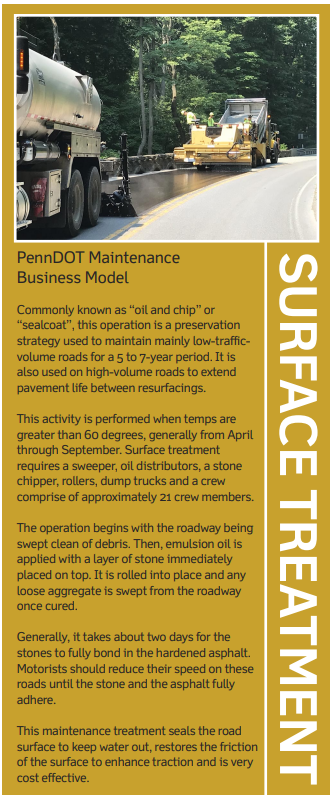

Surface Treatment

Commonly known as “oil and chip” or “sealcoat,” this operation is a preservation strategy used to maintain mainly low-traffic-volume roads for a 5 to 7-year period. It is also used on high-volume roads to extend pavement life between resurfacings.

This activity is performed when temps are greater than 60 degrees, generally from April through September. Surface treatment requires a sweeper, oil distributors, a stone chipper, rollers, dump trucks and a crew comprise of approximately 21 crew members.

The operation begins with the roadway being swept clean of debris. Then, emulsion oil is applied with a layer of stone immediately placed on top. It is rolled into place and any loose aggregate is swept from the roadway once cured.

Generally, it takes about two days for the stones to fully bond in the hardened asphalt. Motorists should reduce their speed on these roads until the stone and the asphalt fully adhere.

This maintenance treatment seals the road surface to keep water out, restores the friction of the surface to enhance traction and is very cost effective.

Click to open PDF. (Printable PDF)

Click to open PDF. (Printable PDF)

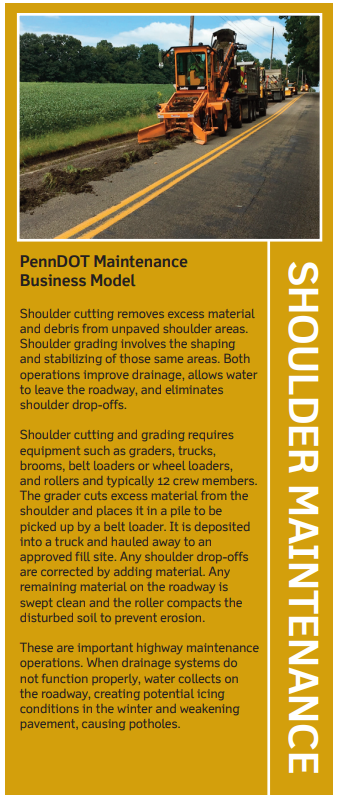

Shoulder Maintenance

Shoulder cutting removes excess material and debris from unpaved shoulder areas. Shoulder grading involves the shaping and stabilizing of those same areas. Both operations improve drainage, allow water to leave the roadway, and eliminate shoulder drop-offs.

Shoulder cutting and grading requires equipment such as graders, trucks, brooms, belt loaders or wheel loaders, and rollers and typically 12 crew members. The grader cuts excess material from the shoulder and places it in a pile to be picked up by a belt loader. It is deposited into a truck and hauled away to an approved fill site. Any shoulder drop-offs are corrected by adding material. Any remaining material on the roadway is swept clean and the roller compacts the disturbed soil to prevent erosion.

These are important highway maintenance operations. When drainage systems do not function properly, water collects on the roadway, creating potential icing conditions in the winter and weakening pavement, causing potholes.

Click to open PDF.(Printable PDF)

Click to open PDF.(Printable PDF)

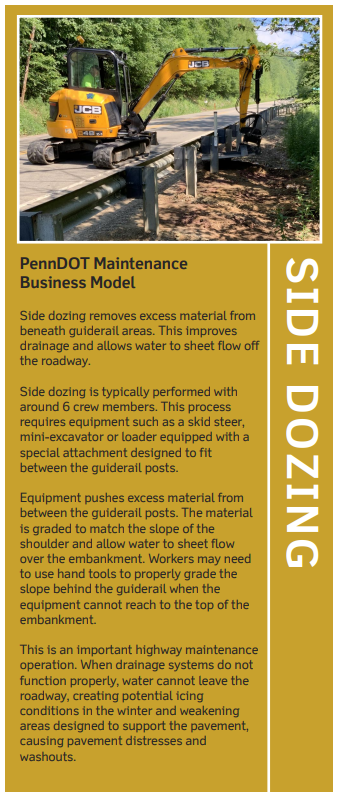

Side Dozing

Side dozing removes excess material from beneath guiderail areas. This improves drainage and allows water to sheet flow off the roadway.

Side dozing is typically performed with around six crew members. This process requires equipment such as a skid steer, mini-excavator or loader equipped with a special attachment designed to fit between the guiderail posts.

Equipment pushes excess material from between the guiderail posts. The material is graded to match the slope of the shoulder and allow water to sheet flow over the embankment. Workers may need to use hand tools to properly grade the slope behind the guiderail when the equipment cannot reach to the top of the embankment.

This is an important highway maintenance operation. When drainage systems do not function properly, water cannot leave the roadway, creating potential icing conditions in the winter and weakening areas designed to support the pavement, causing pavement distresses and washouts.

Click to open PDF.(Printable PDF)

Click to open PDF.(Printable PDF)

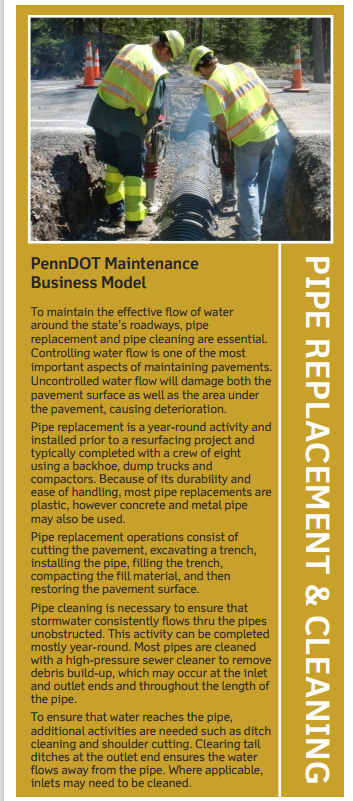

Pipe Replacing & Cleaning

To maintain the effective flow of water around the state’s roadways, pipe replacement and pipe cleaning are essential. Controlling water flow is one of the most important aspects of maintaining pavements. Uncontrolled water flow will damage both the pavement surface as well as the area under the pavement, causing deterioration.

Pipe replacement is a year-round activity and installed prior to a resurfacing project and typically completed with a crew of eight using a backhoe, dump trucks and compactors. Because of its durability and ease of handling, most pipe replacements are plastic, however concrete and metal pipe may also be used.

Pipe replacement operations consist of cutting the pavement, excavating a trench, installing the pipe, filling the trench, compacting the fill material, and then restoring the pavement surface.

Pipe cleaning is necessary to ensure that stormwater consistently flows thru the pipes unobstructed. This activity can be completed mostly year-round. Most pipes are cleaned with a high-pressure sewer cleaner to remove debris build-up, which may occur at the inlet and outlet ends and throughout the length of the pipe.

To ensure that water reaches the pipe, additional activities are needed such as ditch cleaning and shoulder cutting. Clearing tail ditches at the outlet end ensures the water flows away from the pipe. Where applicable, inlets may need to be cleaned.

Click to open PDF.(Printable PDF)

Click to open PDF.(Printable PDF)

Mechanized Patching

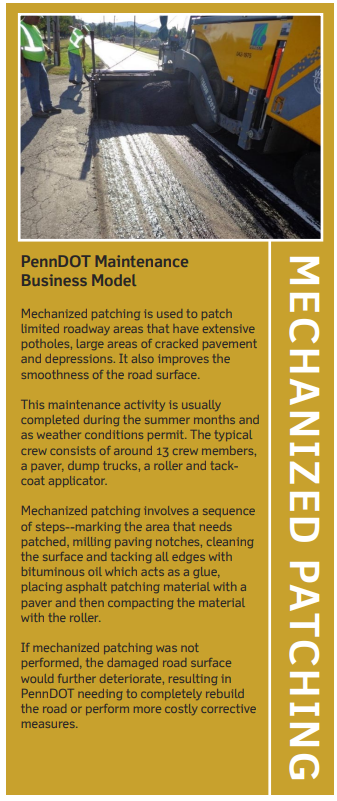

Mechanized patching is used to patch limited roadway areas that have extensive potholes, large areas of cracked pavement and depressions. It also improves the smoothness of the road surface.

This maintenance activity is usually completed during the summer months and as weather conditions permit. The typical crew consists of around 13 crew members, a paver, dump trucks, a roller, and tack-coat applicator.

Mechanized patching involves a sequence of steps: marking the area that needs patched, milling paving notches, cleaning the surface and tacking all edges with bituminous oil which acts as a glue, placing asphalt patching material with a paver and then compacting the material with the roller.

If mechanized patching was not performed, the damaged road surface would further deteriorate, resulting in PennDOT needing to completely rebuild the road or perform more costly corrective measures.

Click to open PDF.(Printable PDF)

Click to open PDF.(Printable PDF)

Manual Patching

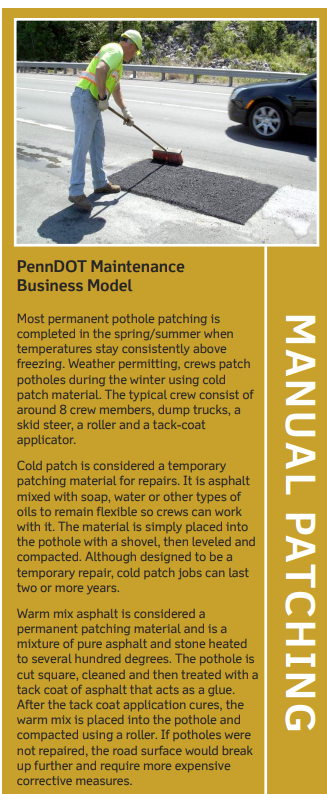

Most permanent pothole patching is completed in the spring/summer when temperatures stay consistently above freezing. Weather permitting, crews patch potholes during the winter using cold patch material. The typical crew consist of around eight crew members, dump trucks, a skid steer, a roller, and a tack-coat applicator.

Cold patch is considered a temporary patching material for repairs. It is asphalt mixed with soap, water or other types of oils to remain flexible so crews can work with it. The material is simply placed into the pothole with a shovel, then leveled and compacted. Although designed to be a temporary repair, cold patch jobs can last two or more years.

Warm mix asphalt is considered a permanent patching material and is a mixture of pure asphalt and stone heated to several hundred degrees. The pothole is cut square, cleaned and then treated with a tack coat of asphalt that acts as a glue. After the tack coat application cures, the warm mix is placed into the pothole and compacted using a roller. If potholes were not repaired, the road surface would break up further and require more expensive corrective measures.

Click to open PDF.(Printable PDF)

Click to open PDF.(Printable PDF)

Crack Seal & Hot Pour Mastic

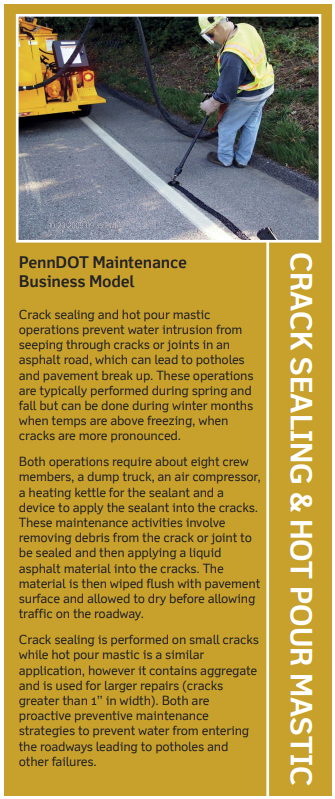

Crack sealing and hot pour mastic operations prevent water intrusion from seeping through cracks or joints in an asphalt road, which can lead to potholes and pavement break up. These operations are typically performed during spring and fall but can be done during winter months when temps are above freezing, when cracks are more pronounced.

Both operations require about eight crew members, a dump truck, an air compressor, a heating kettle for the sealant and a device to apply the sealant into the cracks. These maintenance activities involve removing debris from the crack or joint to be sealed and then applying a liquid asphalt material into the cracks. The material is then wiped flush with pavement surface and allowed to dry before allowing traffic on the roadway.

Crack sealing is performed on small cracks while hot pour mastic is a similar application, however it contains aggregate and is used for larger repairs (cracks greater than 1” in width). Both are proactive preventive maintenance strategies to prevent water from entering the roadways leading to potholes and other failures.

Click to open PDF.(Printable PDF)

Click to open PDF.(Printable PDF)

Pre-Winter Operations

Winter preparedness is a year-round activity in

which PennDOT expends a lot of time and

resources in order to provide safe and passable

roads when winter precipitation is falling.

Activities such as repairing equipment during the

summer months to ensure it is ready; facilities

being updated to store winter materials safely

and environmentally friendly; ordering various

supplies and winter de-icing materials so they are

on hand when needed and devoting time to train

our workforce on proper snow removal techniques

are all keys to successful planning.

We also take time to meet with key stakeholders

to plan and coordinate prior to winter. Other state

DOT’s, local municipalities, EMA/911 centers,

state and local police, fire and EMS companies,

along with school busing all play an important

part in winter operations.

PennDOT builds snow maps for each truck in our

fleet to ensure all roads are covered. Contingency

plans are developed on how to shift resources to

higher-volume roads or other areas based on

intensity of winter storms. Our staff also conducts

dry runs, essentially driving each snow route in

good weather to identify hazards or safety

concerns that need addressed prior to winter,

while also noting turn around areas and other

important features.

To learn more about our winter preparations, or to

make sure that both you and your vehicle are

ready for ice and snow, visit the

Winter section of our website.

Click to open PDF.(Printable PDF)

Click to open PDF.(Printable PDF)

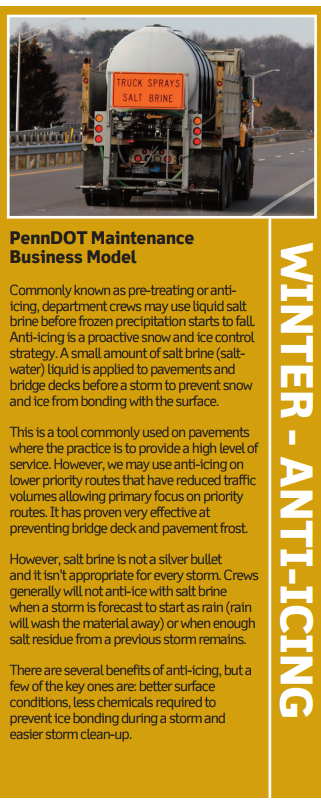

Winter Anti-Icing

Commonly known as pre-treating or anti�icing, department crews may use liquid salt

brine before frozen precipitation starts to fall.

Anti-icing is a proactive snow and ice control

strategy. A small amount of salt brine (salt-water) liquid is applied to pavements and

bridge decks before a storm to prevent snow

and ice from bonding with the surface.

This is a tool commonly used on pavements

where the practice is to provide a high level of

service. However, we may use anti-icing on

lower priority routes that have reduced traffic

volumes allowing primary focus on priority

routes. It has proven very effective at

preventing bridge deck and pavement frost.

However, salt brine is not a silver bullet

and it isn't appropriate for every storm. Crews

generally will not anti-ice with salt brine

when a storm is forecast to start as rain (rain

will wash the material away) or when enough

salt residue from a previous storm remains.

There are several benefits of anti-icing, but a

few of the key ones are: better surface

conditions, less chemicals required to

prevent ice bonding during a storm and

easier storm clean-up.

Click to open PDF.(Printable PDF)

Click to open PDF.(Printable PDF)

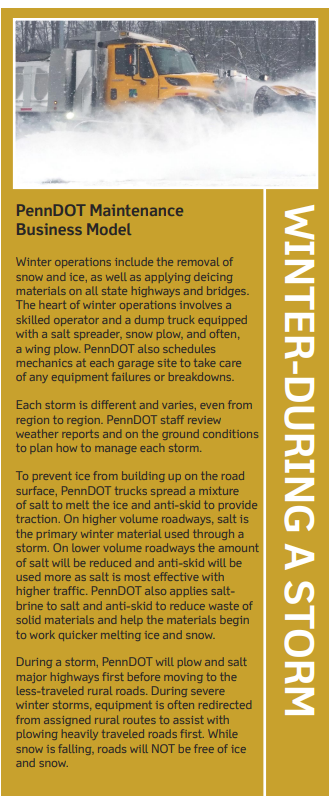

During a Winter Storm

Winter operations include the removal of

snow and ice, as well as applying deicing

materials on all state highways and bridges.

The heart of winter operations involves a

skilled operator and a dump truck equipped

with a salt spreader, snow plow, and often,

a wing plow. PennDOT also schedules

mechanics at each garage site to take care

of any equipment failures or breakdowns.

Each storm is different and varies, even from

region to region. PennDOT staff review

weather reports and on the ground conditions

to plan how to manage each storm.

To prevent ice from building up on the road

surface, PennDOT trucks spread a mixture

of salt to melt the ice and anti-skid to provide

traction. On higher volume roadways, salt is

the primary winter material used through a

storm. On lower volume roadways the amount

of salt will be reduced and anti-skid will be

used more as salt is most effective with

higher traffic. PennDOT also applies salt-brine to salt and anti-skid to reduce waste of

solid materials and help the materials begin

to work quicker melting ice and snow.

During a storm, PennDOT will plow and salt

major highways first before moving to the

less-traveled rural roads. During severe

winter storms, equipment is often redirected

from assigned rural routes to assist with

plowing heavily traveled roads first. While

snow is falling, roads will NOT be free of ice

and snow.

Click to open PDF.(Printable PDF)

Click to open PDF.(Printable PDF)

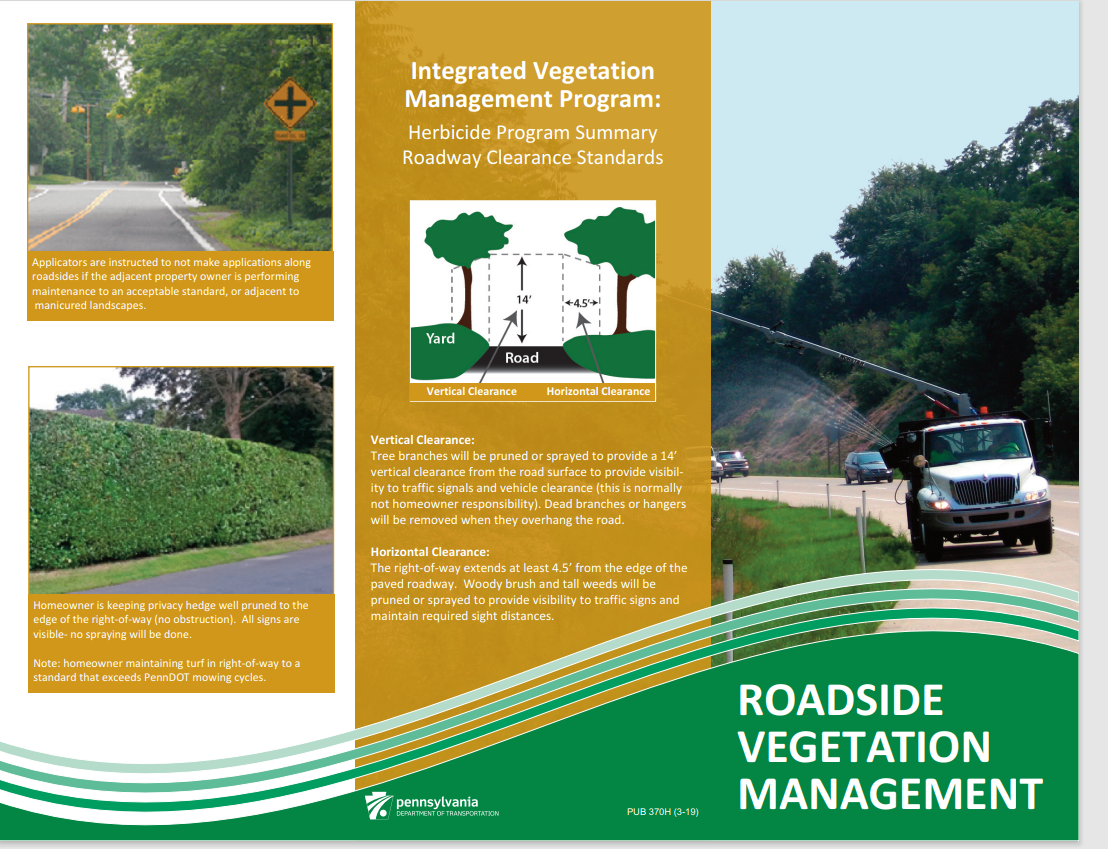

Vegetation Management

The objective of this program is to maintain a safe travel way that is free from obstructing vegetation. Unobstructed roadsides provide increased visibility of: signs and traffic control devices, motorists, bicyclists, pedestrians and animals approaching the roadway (especially challenging at severe horizontal and vertical curves). Additionally, well maintained roadsides can improve drainage function and prolong the life of the entire roadway.

Mowing, herbicide spraying and selected tree thinning are the processes that make-up the management program. PennDOT mows approximately 112,000 acres annually from May through October. Mowing frequency is determined by their traffic volume and posted speed limit as well as growth height.

Click to open PDF.(Printable PDF)

Click to open PDF.(Printable PDF)

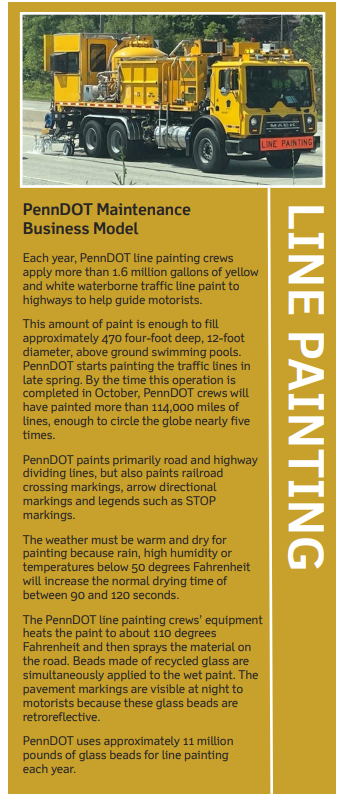

Line Painting

Each year, PennDOT line painting crews apply more than 1.6 million gallons of yellow and white waterborne traffic line paint to highways to help guide motorists.

This amount of paint is enough to fill approximately 470 four-foot deep, 12-foot diameter, above ground swimming pools. PennDOT starts painting the traffic lines in late spring. By the time this operation is completed in October, PennDOT crews will have painted more than 114,000 miles of lines, enough to circle the globe nearly five times.

PennDOT paints primarily road and highway dividing lines, but also paints railroad crossing markings, arrow directional markings and legends such as STOP markings.

The weather must be warm and dry for painting because rain, high humidity or temperatures below 50 degrees Fahrenheit will increase the normal drying time of between 90 and 120 seconds.

The PennDOT line painting crews’ equipment heats the paint to about 110 degrees Fahrenheit and then sprays the material on the road. Beads made of recycled glass are simultaneously applied to the wet paint. The pavement markings are visible at night to motorists because these glass beads are retroreflective.

PennDOT uses approximately 11 million pounds of glass beads for line painting each year.

Click to open PDF.(Printable PDF)

Click to open PDF.(Printable PDF)

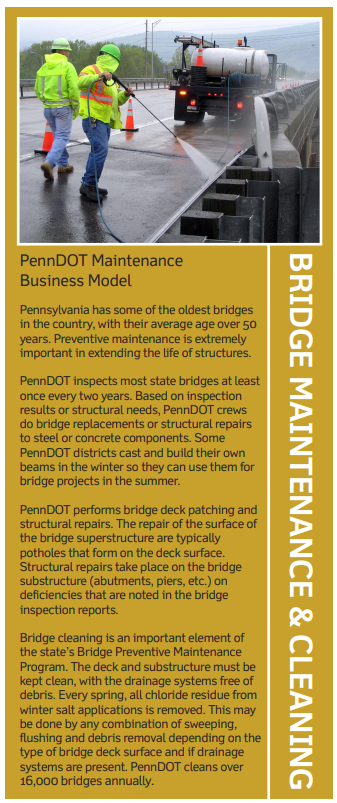

Bridge Maintenance & Cleaning

Pennsylvania has some of the oldest bridges in the country, with their average age over 50 years. Preventive maintenance is extremely important in extending the life of structures.

PennDOT inspects most state bridges at least once every two years. Based on inspection results or structural needs, PennDOT crews do bridge replacements or structural repairs to steel or concrete components. Some PennDOT districts cast and build their own beams in the winter so they can use them for bridge projects in the summer.

PennDOT performs bridge deck patching and structural repairs. The repair of the surface of the bridge superstructure are typically potholes that form on the deck surface. Structural repairs take place on the bridge substructure (abutments, piers, etc.) on deficiencies that are noted in the bridge inspection reports.

Bridge cleaning is an important element of the state’s Bridge Preventive Maintenance Program. The deck and substructure must be kept clean, with the drainage systems free of debris. Every spring, all chloride residue from winter salt applications is removed. This may be done by any combination of sweeping, flushing and debris removal depending on the type of bridge deck surface and if drainage systems are present. PennDOT cleans over 16,000 bridges annually

Click to open PDF.(Printable PDF)

Click to open PDF.(Printable PDF)

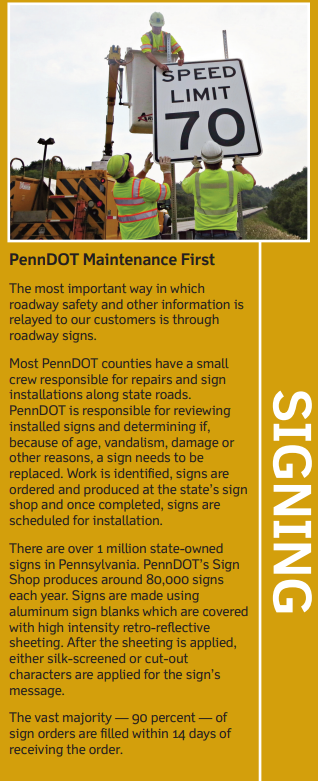

Signing

The most important way in which roadway safety and other information is relayed to our customers is through roadway signs.

Most PennDOT counties have a small crew responsible for repairs and sign installations along state roads. PennDOT is responsible for reviewing installed signs and determining if, because of age, vandalism, damage or other reasons, a sign needs to be replaced. Work is identified, signs are ordered and produced at the state’s sign shop and once completed, signs are scheduled for installation.

There are over 1 million state-owned signs in Pennsylvania. PennDOT’s Sign Shop produces around 80,000 signs each year. Signs are made using aluminum sign blanks which are covered with high intensity retro-reflective sheeting. After the sheeting is applied, either silk-screened or cut-out characters are applied for the sign’s message.

The vast majority — 90 percent — of sign orders are filled within 14 days of receiving the order.